| Model |

Thermal Capacity |

Thermal CapacityControl System |

Fuel Type |

Size |

Weight |

Power |

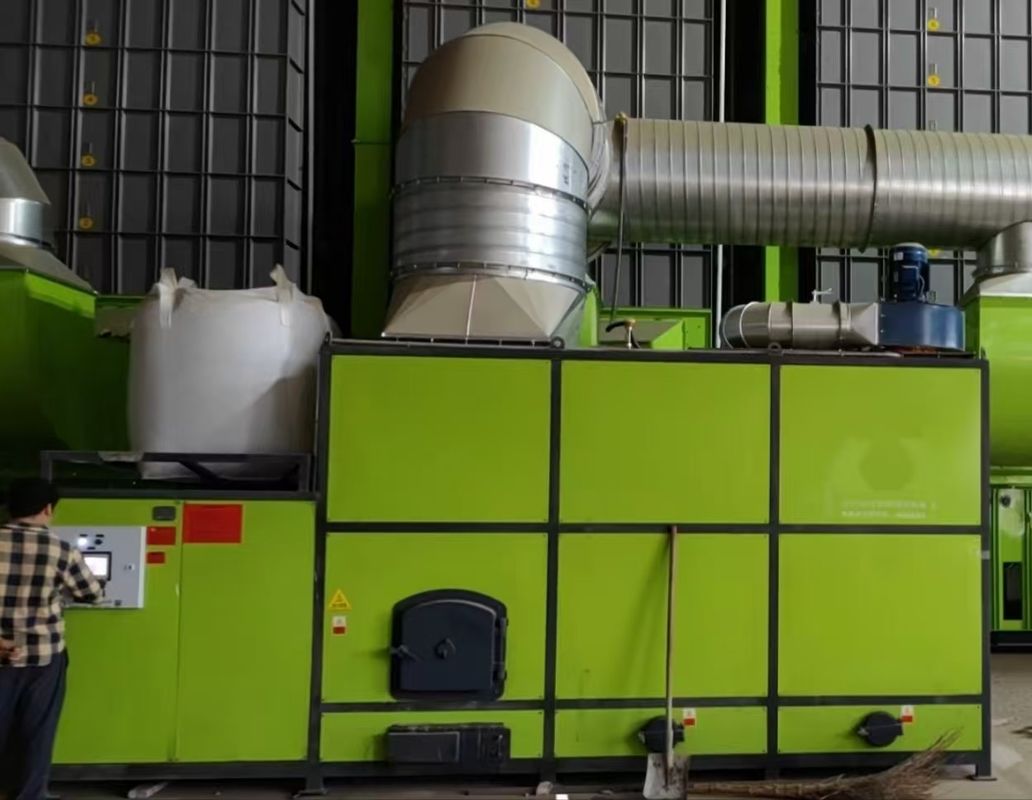

| 5L-60 |

600,000kcal/h |

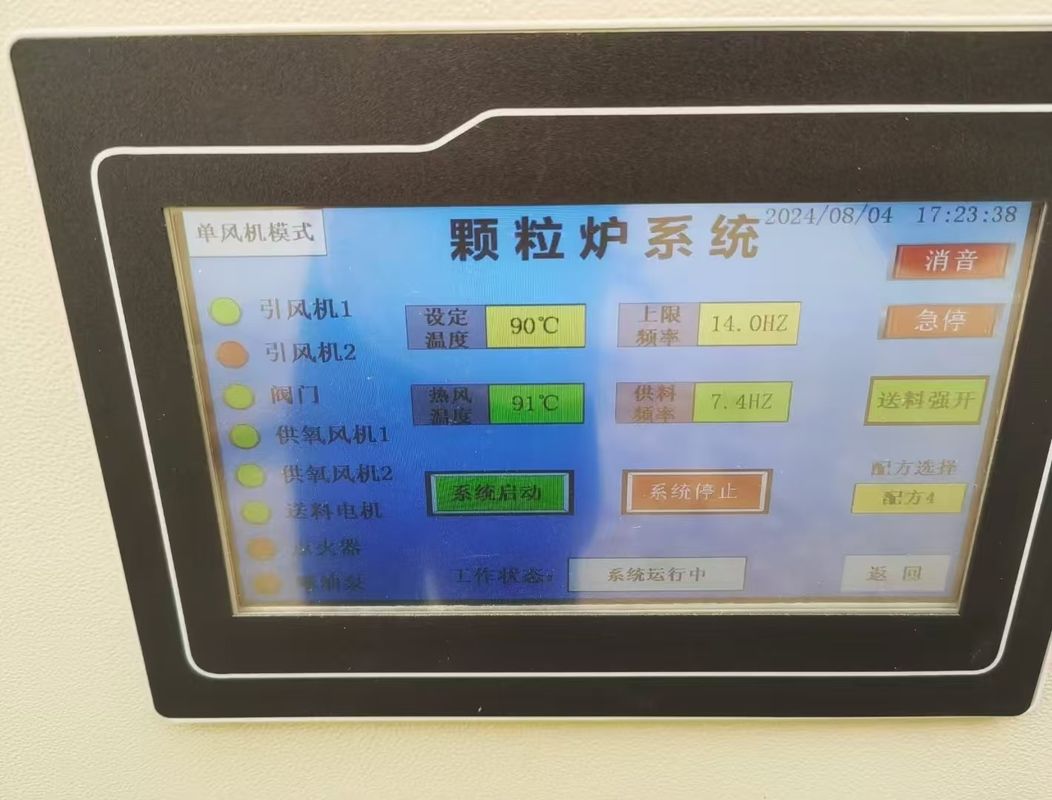

Advanced PLC with IoT connectivity |

Rice husk and biomass materials |

3500*1500*1800mm |

1600kg |

4.15kw |

Introduction to Fuel/Gas Hot Air Furnaces

Fuel/Gas Hot Air Furnaces are composed of a burner and a furnace controller. The gas burner consists of five integrated systems: air supply, ignition, monitoring, fuel delivery, and electronic control. As the latest generation of hot air generation equipment, it utilizes fuel combustion through the burner, which undergoes high-efficiency purification to produce clean hot air. This hot air directly contacts and heats materials for drying purposes. Compared to steam-based or other indirect heating methods, this technology reduces fuel consumption by approximately 50% while ensuring no compromise in the quality of dried products. Consequently, direct high-purity hot air systems are fully suitable for efficient drying operations.

After combustion, the resulting high-temperature gases are mixed with external air to reach a precisely controlled temperature before being directly introduced into the drying chamber. Here, they interact with the materials to heat and evaporate moisture, yielding the final dried product. To effectively harness the thermal energy from fuel combustion, a dedicated combustion system is essential. Our company employs imported burners paired with advanced combustion control systems, ensuring safe, stable, and highly efficient operation.

Product Features:

1.High Thermal Efficiency: Utilizes advanced heat-exchange technology and heat-resistant steel materials, featuring a compact design and extended service life.

2.Premium Stainless Steel Combustion Chamber: Equipped with a dual-layer protective structure in high-temperature zones, ensuring precision engineering and enhanced durability.

3.AI-Enhanced Control System: Incorporates advanced artificial intelligence with self-learning capabilities, enabling real-time monitoring, adjustment, and control of the combustion process for precise temperature maintenance.

4.Smart IoT Connectivity: Enables seamless machine-user interaction, facilitating remote operation, real-time monitoring, and simplified after-sales support for greater convenience.

5.Stable and Safe Operation: Offers automatic temperature control within an adjustable range of 45°C to 120°C, ensuring reliable performance.

6.Patented Heat Exchange Design: Features an optimized heat exchange piping system for rapid heating and thermal efficiency exceeding 90%.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!